{{ sigdata.reliabtittwo }}

| Item | Required Characteristics | Test Method / Condition |

|---|---|---|

|

High Temperature Storage Test Reference Documents: GB/T 2423.2-2008 Method Bb |

1.No significant defects in appearance.

2.ΔL/L≦10% (Mn-Zn: ΔL/L≦30% ) 3.ΔQ/Q≦30% (Only SMD series) 4.ΔDCR/DCR≦10% |

Temperature: N±2℃ (N: Follow the product specification for the setting.) Time : 96±2 hours Place the samples for one hour at room temperature and test them within two hours.

|

|

Low Temperature Storage Test Reference Documents: GB/T 2423.1-2008 Method Ab |

1.No significant defects in appearance.

2.ΔL/L≦10% (Mn-Zn: ΔL/L≦30% ) 3.ΔQ/Q≦30% (Only SMD series) 4.ΔDCR/DCR≦10% |

Temperature: M±2℃ (M: Follow the product specification for the setting) Time : 96±2 hours Place the samples for one hour at room temperature and test them within two hours.

|

|

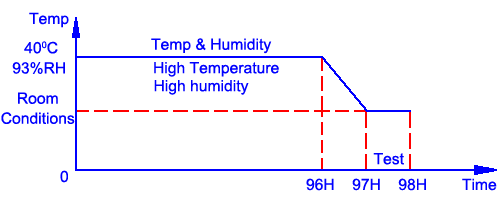

Humidity Test Reference Documents: GB/T 2423.3-2016 |

1.No significant defects in appearance.

2.ΔL/L≦10% (Mn-Zn: ΔL/L≦30% ) 3.ΔQ/Q≦30% (SMD series only) 4.ΔDCR/DCR≦10% |

Temperature: 40±2℃ , Humidity: 93±3%RH Time : 96±2 hours Place the samples for one hour at room temperature and test them within two hours.

|

|

Thermal Shock Test Reference Documents: GB/T 2423.22-2012 Method Na |

1.No significant defects in appearance.

2.ΔL/L≦10% (Mn-Zn: ΔL/L≦30% ) 3.ΔQ/Q≦30% (SMD series only) 4.ΔDCR/DCR≦10% T: 15Min if weight≦28g M: low temp. setting T: 30Min if 28g≦weight≦136g N: high temp. setting |

Start at M℃ for T time, rush to N ℃ for T time as one cycle, go through 20 cycles.

|

|

Solderability Test Reference Documents: GB/T 2423.28-2005 Method Ta |

Terminals must have 95% minimum solder coverage. |

1.Dip the terminals in the flux then in the solder pot at 245±5℃ for 5 seconds. 2.Solder: lead free 3.Flux: rosin flux |

|

Heat endurance of Reflow soldering Reference documents: GJB 360B-2009 Method 210 |

1.No significant defects in appearance. 2.ΔL/L≦10% (Mn-Zn: ΔL/L≦30% ) 3.ΔQ/Q≦30% (SMD series only) 4.ΔDCR/DCR≦10% |

1.Refer to the above reflow curve and go through the reflow for twice. 2.The peak temperature : 260+0/-5℃ 3.The reflow test conditions are based on the testing instruments available in 3L

|

|

Vibration test Reference documents: GB/T 2423.10-2019 |

1.No significant defects in appearance. 2.No short and no open. |

Apply frequency 10~55~10Hz and amplitude 1.5mm, 1 min/cycle in X , Y and Z direction for 2 hours each. (total 6 hours)

|

|

Terminal strength(SMT) Reference documents: GB/T 2423.60-2008 |

1. HPI / SMD(V) / SMB / SMI / SMW series:Applied force:5N Duration: 10sec 2.Other SMT series besides the above series:Applied force:10N Duration: 10sec 3.Solder paste thickness:0.12mm 4.Meet the above requirements without any loose terminal. |

Solder the test samples to the PCB through 245 ℃ reflow, apply a standard force on the side of the test samples for 10 seconds.

|

|

Terminal strength(DIP) Reference documents: GB/T 2423.60-2008 |

1.Terminal diameter(d) mm 0.35<d≤0.50 Applied force:5N Duration: 10sec 2.Terminal diameter(d) mm0.50<d≤0.80 Applied force:10N Duration: 10sec 3.Terminal diameter(d) mm0.80<d≤1.25 Applied force:20N Duration: 10sec 4.Terminal diameter(d) mmD>1.25 Applied force:40N Duration: 10sec 5.Meet the above requirements without any loose terminal. |

Pull Force:the force shall be applied gradually to the terminal and then maintained for 10 seconds.

|

|

Drop test Reference documents: GB/T 2423.7-2018 |

1.No case deformation or change in appearance. 2.No short and no open. |

Drop the packaged products from 1m high in 1 angle,3 ridges and 6 surfaces, twice in each direction. |